Luminaire for Quality Control

Custom-made LED lighting for quality control (QC) areas plays a crucial role in ensuring accurate inspection, defect detection, and color consistency across various industries. Here’s how tailored LED solutions enhance QC processes:

Key Benefits of Custom LED Lighting for Quality Control Areas

| Benefit | Description | Impact on QC Process |

|---|---|---|

| High Color Rendering Index (CRI 90+ or 95+) | Custom LEDs with high CRI provide accurate color differentiation, reducing misjudgment. | - Ensures true-to-life color assessment - Prevents defects in textiles, printing, automotive, and food industries |

| Adjustable Color Temperature (CCT 3000K-6500K) | Tunable white LEDs allow workers to match lighting conditions to specific materials and production needs. | - Ideal for industries requiring consistent color matching (e.g., paint, fabric, plastics) |

| Glare-Free & Uniform Illumination | Diffused LED designs reduce harsh shadows and reflections. | - Enhances visual accuracy, reducing eye strain in detailed inspections |

| Flicker-Free & Stable Output | High-quality LED drivers eliminate flickering, preventing visual fatigue. | - Increases worker efficiency in prolonged QC tasks |

| Directional Lighting & Task-Specific Beam Angles | Custom optics focus light precisely on inspection areas without waste. | - Improves detection of surface defects, scratches, and irregularities |

| Integration with Machine Vision Systems | LEDs with specific wavelengths (e.g., UV, IR) enhance automated QC processes. | - Detects invisible defects, contamination, and inconsistencies |

| Energy Efficiency & Long Lifespan | LED solutions consume less power and have 50,000+ hours lifespan. | - Reduces maintenance and operational costs |

| Smart Controls & Dimming | IoT-connected LEDs allow automatic brightness adjustments based on task requirements. | - Optimizes energy use while maintaining consistent inspection conditions |

Industries That Benefit from Custom LED for QC Areas:

✅ Manufacturing: Detecting scratches, dents, or assembly defects

✅ Electronics: PCB soldering & micro-component inspection

✅ Automotive: Paint quality, surface finish, and part inspection

✅ Textiles & Printing: Color consistency and defect detection

✅ Food Processing: Identifying contamination and spoilage

Luminaire for Special Requirements

There are also case where we need to develop special luminaire for special case. Often there are a lot of limitation and requirement that makes us to do better on luminaire planning. Our best solution would be creating specialized luminaire for said area.

Our cases are below:

For both project we develop custom luminaire since the requirement is pretty difficult. The left image wanted luminaire with medium elevation, minimal glare but also lightweight and high brightness. There are also electrical and budget limitation. In the other hand, user of right image wanted a wide degree of luminaire, very low glare but in very low height of ceiling. Both of those cases are not very ordinary on lighting fixture that is why we need to develop it ourselves.

Horticultural Luminaire

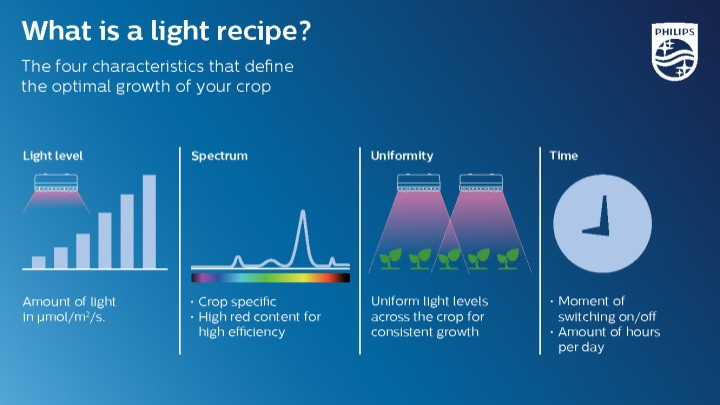

As previously mentioned, LED lighting offers precise spectrum control, which means that the light can be tailored to the specific needs of plants; the classic grow lamps radiate more strongly in magenta and blue colors. However, different wavelengths of light are required for different stages of plant growth, and LED lighting can provide the optimal spectrum for each stage. Another advantage is that it produces less heat and infrared radiation than traditional lighting methods, thus reducing the risk of heat stress on plants under high illumination levels. This is especially important in indoor farming and greenhouse cultivation, where temperature control is critical.

Above image are summary how lighting impacting crops (credit from Phillips), where lighting can definitely help. Indonesia in equatorial place definitely aren't running out of sunlight anytime soon, but for several unique plants that able to grow 24/7, custom luminaire will definitely help.

Animal Husbandry Luminaire

Custom LED lighting enhances productivity, reduces costs, and improves animal welfare in poultry, dairy, swine, and aquaculture farms. Implementing tailored spectrums, dimming schedules, and smart controls provides a competitive edge in modern animal husbandry.

It is because proper and adequate lighting is crucial for animal well-being and growth, and LED lighting can provide the exact spectrum of light needed for different stages of animal development. Below are some of the benefit of LED for animal husbandry.

| Animal Husbandry | Custom LED Benefits | Effects on Production |

|---|

| Poultry (Broilers & Layers) | - Red & green LEDs enhance growth rates - Warm white & red light stimulate egg production - Flicker-free & dimmable LEDs reduce stress | - Faster weight gain & better feed conversion - Increased egg-laying frequency & quality - Lower aggression & improved welfare |

| Dairy Cattle | - Extended daylight (16-18 hours) increases milk yield - Proper lighting schedules enhance fertility | - 10-15% increase in milk production - Improved reproductive cycles & fertility |

| Aquaculture (Fish & Shrimp Farming) | - Blue & green LEDs improve fish metabolism & growth - UV & blue light reduce bacterial growth | - Faster growth rates & higher survival rates - Lower risk of disease & improved water quality |

| Other Livestock (Goats, Sheep, Horses) | - Simulated natural daylight improves breeding cycles - Stable lighting conditions reduce stress | - Enhanced reproduction & healthier animals - Improved feed efficiency & reduced illness |